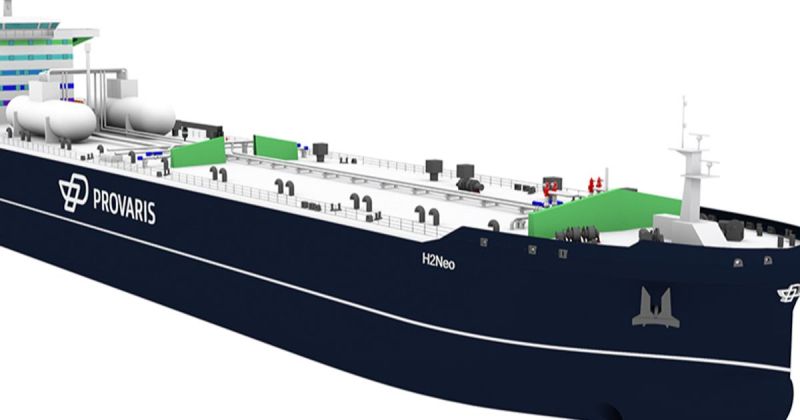

Provaris Energy engages DNV for FEED review ahead of Prototype Tank build

Provaris Energy Ltd (ASX:PV1, OTC:GBBLF) has engaged leading classification society DNV to issue a Front-End Engineering Design (FEED) Statement for the company’s proprietary H2Neo carrier design and approval of its proprietary Prototype Tank.

DNV will apply its expertise towards the review and approval of Provaris’ H2Neo carrier's proprietary hydrogen cargo containment system.

This is an important step before Provaris begins the construction and testing of a Prototype Tank during the current quarter.

Successful completion of Prototype Tank testing will secure all necessary design and technology development approvals to commit to shipbuilding projects for Provaris’ H2Neo compressed hydrogen carriers.

“Exciting phase”

Provaris’ chief technical executive officer Per Roed said: “The Prototype testing program is an exciting phase of our technical and H2Neo approvals program.

“We continue to see an increasing demand for safe and cost-effective solutions to store and transport gaseous compressed hydrogen, and to be able to validate our proprietary solution through Prototype testing can be a game changer to unlocking a significant market opportunity.

"Our focus has been to establish a strong team of contributors and partners on this journey, and the engagement of DNV will further strengthen the N2Neo Class approval.”

The H2Neo carrier received FEED design approval in December 2022, with final approval for construction subject to the completion of a prototype of the proprietary containment tank design being constructed and tested to the satisfaction of Class requirements.

Long-term experience

DNV will leverage its long-term experience with maritime storage and deep understanding of the transportation of numerous gases in compressed and liquid forms with resources from its Gas Carrier Excellence Centre throughout the construction and testing process.

The world-leading classification society also has intimate knowledge of, and experience with, Prodtex’s manufacturing processes and capabilities for complex steel structures, allowing for an effective collaborative effort to successfully execute on the multilayered welded steel plates required in the Prototype Tank construction and testing program.

Construction remains on track to begin this quarter with completion expected by the end of the second quarter of 2024.

Provaris will work with DNV to qualify the H2Neo design and hydrogen containment tanks.

Additional parties involved in the work program located in Norway include Prodtex AS for construction and SINTEF, who will be responsible to perform the prototype testing and reporting.

Linchpin of energy transition

DNV’s global business director Gas Carriers Martin Cartwright said: “Transporting hydrogen securely and efficiently is going to be one of the linchpins of the energy transition.

“To make sure that this market can really take off, we need to draw on the lessons we have learned from other fuels and build from a sound technical foundation.

“This is why we are very pleased to be working with Provaris, bringing DNV’s experience, expertise and cooperative spirit to help them deliver this innovative concept.”

Illustration of Prodtex’s robotic cell for the construction and testing of the Prototype Tank.

The prototype tank design combined with the automated construction process, which utilizes robotic laser welding, will enable Provaris to scale tanks up from 1-tonne capacity to the full-scale tanks required for the H2Neo carrier.

A production cell located in Norway, using robotic laser welding can achieve significant cost benefits through a reduction in energy and labor content, achieve rigorous quality assurance, safety and regulatory standards, and reduce the CO2 footprint when compared to manufacturing alternatives in Asia.

Potential opportunities

This work could lead to further opportunities for Provaris with numerous inbound enquiries received over the past two years about the potential to supply small-scale hydrogen storage tanks using its proprietary carbon steel containment tank design.

Typically, the requirement has been for industrial applications at a scale of 1 to 5 tonnes of hydrogen capacity.

Together with Prodtex, planning is underway to confirm construction time and costs for 1-tonne capacity tanks based on the Prototype Tank design and using the proprietary design of a multi-layered carbon steel tank with liner.

Suitable industry applications include marine bunkering and onboard storage tanks for new or modified ships implementing compressed hydrogen as the fuel source.

Discussions are underway with ship designers and owners seeking alternatives to carbon fibre type 4 tanks stacked in containerized solutions.

HRS bulk storage potential

An example of a large addressable market includes bulk storage at Hydrogen Refueling Stations (HRS) that require a minimum daily capacity of 1-tonne of storage as specified by the recent Alternative Fuels Infrastructure Regulation (AFIR) legislation passed by the European Union in September 2023.

The EU has identified 657 HRS sites to be deployed across the 27 member states by 2027, meaning deployment must start in 2025.

Subject to the successful completion of the Prototype Tank, the production and sale of tanks could provide Provaris with an early revenue and cash-generating business in late calendar year 2024.

Discussions are underway with various European industrial partners regarding their hydrogen storage requirements.